UV Resistant Epoxy with Super-UV Inhibitor Additive

What is UV Inhibitor for Epoxy Resin?

UV inhibitor is an additive for epoxy resins and polyurethanes that protects against the impacts of ultraviolet (UV) rays. Because epoxies and polyurethanes are not completely resistant to UV, a UV inhibitor can be added to the formula to absorb UV rays and protect from yellowing or ambering.

Super-UV Inhibitor Additive for Epoxy Resin

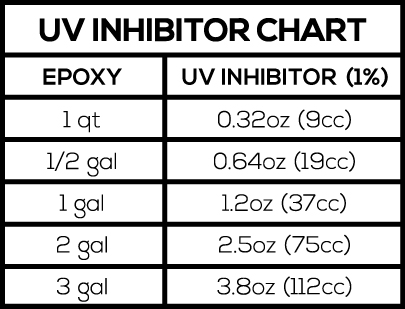

Super-UV Inhibitor Additive is the best clarity defender for epoxy resin or polyurethane projects. Designed with long-term quality and effectiveness in mind, this proprietary formula is the perfect solution for projects that will have occasional to frequent sun exposure. Super-UV was developed to work perfectly with Superclear Epoxy Resin Systems epoxies.

Superclear Epoxy Resin Systems epoxies already have some Super-UV Inhibitor Additive in their proprietary formulations. However, since this solution can significantly increase the cost of a kit, we wanted to provide makers with the option for additional UV protection in their projects. Check out our epoxy variations to see which one would work best for your application!

How does Super-UV work chemically?

To ensure long lasting clarity in polymers like epoxy resin and polyurethane projects, Super-UV uses HALS in the propriety formula. HALS, or Hindered Amine Light Stabilizer, works to absorb any yellowing from UV rays. When added to epoxy resin or polyurethane, the UV inhibitor consumes the effects of UV instead of being taken in by the polymer.

Think of Super-UV like a sacrificial lamb; the UV inhibitor takes the place of the polymer by absorbing all yellowing first, which then destroys the “lamb” instead of the epoxy. With Super-UV acting as the first line of defense, these polymers can now maintain clarity significantly longer!