Deep Pour Epoxy Guide

Introduction

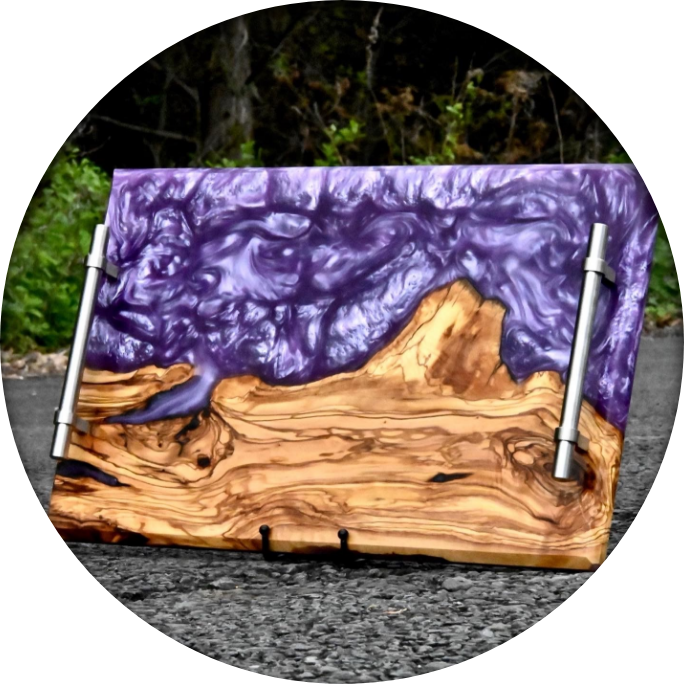

At Super Epoxy Systems, we are passionate about providing the best possible solutions for all your woodworking needs. Our Liquid Glass® Deep Pour Epoxy formulation was born from our dedication to excellence, providing exceptional quality and unsurpassed performance. With our deep pour epoxy resin, you can have peace of mind knowing that your projects will not just appear stunning, but will endure for many years to come.

What’s the Point?

This article is for both experienced woodworkers and newcomers alike, and aims to provide the following:

- Focus on Advantages & Uses of Deep Pour Epoxy

- Properties and Formulations

- Multiple Applications

- Illustrate How to use Deep Pour Epoxy

1 Comment. Leave new

Is there a benefit to using a pressure pot to reduce any bubbles when casting a wood hybrid project?